Welcome to our monthly progress update! There is no shortage of news from this last month, so let’s go through them one by one!

Plastic case

We’ve already received samples of the bottom case parts, the buttons on the plastic case, and the top left and top right parts are well on their way. The following image is the top left part of the case with the sprue left on it.

As it turns out, the ejector pins of the top left mold are unable to eject the part properly, so our contractor is in the process of adding an extra pin. We shall soon receive all the plastic parts of the case to evaluate them.

Palm rest

In the last update, we showed you the 3D printed prototypes of the palm rest. We also showed you foams of different types that could go into the palm rest. In the meantime, we’ve been thinking about using an alternative material to foam: wood.

Wood palm rests are considered to be the most premium solution. They’re nice to touch, pleasing to the eye, and last longer than foam palm rests. This is how our current palm rest prototype looks like.

You can see the base plates of the palm rest on top. They’re milled out of solid aluminium, then anodized, and finally covered with lacquer. The left one was powder coated with glossy lacquer that did not change the black anodized color, and the right was covered with matte lacquer that changed the black anodized color quite a bit.

The current base plates feel extremely robust and look pretty nice, but to make them even nicer, we’re thinking about powder coating them black instead of anodizing them. This would result in a solid, semi-gloss, black color. We’ll give it a try later.

As for the wood parts, beech wood was used which got slightly dyed, and then a glossy lacquer layer was applied. The gloss is too much, so we plan to settle with semi-gloss lacquer, and we’ll probably end up using a darker brown paint.

LED display

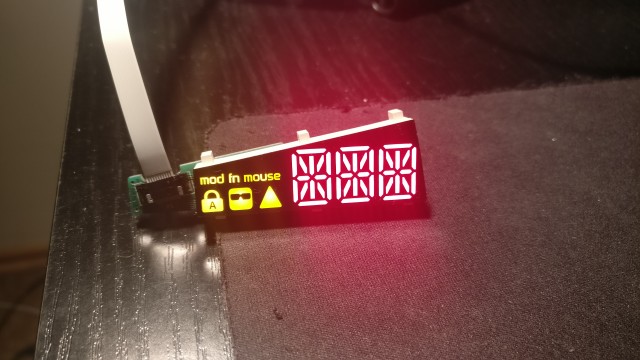

The last time we updated you, we mentioned that our LED display was having ghosting issues. This was caused by the white LEDs whose forward voltage was significantly higher than the other red and yellow LEDs.

We haven’t found a viable solution regarding the white LEDs, so we ended up using yellow LEDs for the icons. This makes the charlieplexed LED matrix use only red and yellow LEDs whose forward voltage is similar.

This simple fix has fully resolved the ghosting issue. Ghosts busted!

Bridge cable

One would think that the bridge cable is a no-brainer. After all, it’s just a simple spiral cable, so let’s just pick a random cable from any manufacturer and call it a day, right? As it turns out, that’s not exactly the case.

In the spirit of future-proofing the UHK for backlighting, I tested the bridge cable with all switch LEDs on to see whether it carries enough current to the LEDs.

It’s clear that the right half is brighter than left. When connected via the board-to-board connector, the brightness level evened out the halves. It became apparent that the voltage drop of the bridge cable was very high.

I figured out that there are two factors that affect this issue, which are the diameter and the material of the wires inside of the cable. My bridge cable was made of copper-clad steel instead of pure copper, which conducts electricity much better. As for the diameter, the wires of my cable were extremely thin.

I then started contacting spiral cable manufacturers to learn more details and find the best option. As it turns out, 24-30 AWG diameter wires can be crimped to RJ jacks, so I asked for 24, 26, 38, and 30 AWG copper cable samples.

After testing them, I could confirm that the resistance of these cables was much lower than my original cables, and lighting was even across the keyboard halves with any of them. In order to minimize the voltage drop, I wanted to pick the thickest 24 AWG cable.

That’s when the manufacturer warned me that 24 AWG cables may not retain their shape after stretching them moderately, which was an issue I was able to confirm. I figured that it’s the plastic exterior of these cables that provide the flexibility. There was too much copper in thicker cables, which made them not retain their shape after flexing. After testing the samples, I figured that 28 AWG and 30 AWG retained their shape well. So I picked the thicker 28 AWG one, and this will be our final cable.

Lesson of the story: not all cables are created equal, and the devil is in the details!

Electrical issues

The UHK will have to pass EMC tests so that we can stick FCC and CE logos on the back, allowing for worldwide distribution. Being aware of this issue, I knew the time had come to send one of our prototypes to an electrical engineer to be investigated from an EMC standpoint.

Luckily, a friend of mine, Robi, just happens to be an electrical engineer. He’s not even a mediocre engineer, but a great one, and he was very willing to take a peek at our prototype.

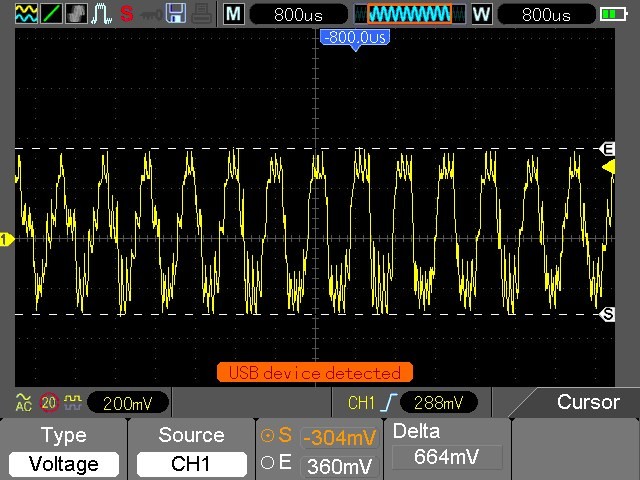

After receiving the prototype, Robi was eager to get his hands dirty. The first thing he did is hook his prototype up to a scope. The results were somewhat worrying.

He told me that given this heavy electrical noise, there is not a fighting chance we’ll pass EMC tests.

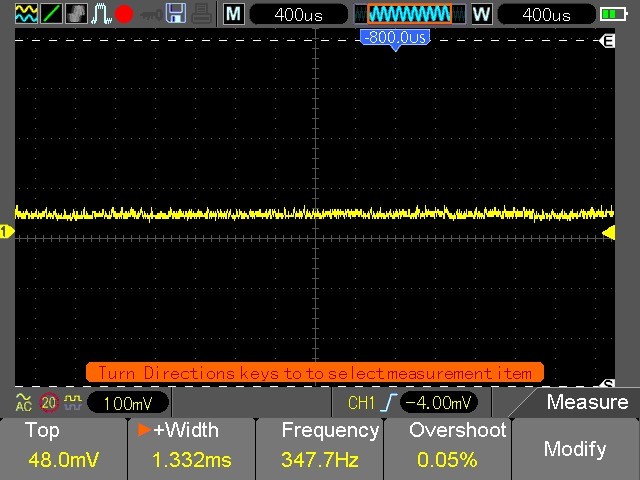

About 5 minutes later he told me that he had bad news and good news. The good news is that he managed to solve the electrical noise issue.

The bad news is that I wouldn’t like the solution.

The elephant in the room is the monstrous electrolytic capacitor soldered onto the PCB. If you’re afraid that it won’t fit inside of the UHK case, you guessed it right!

Luckily, using multiple SMD ceramic capacitors can provide sufficiently high capacitance. Robi also suggested using a ferrite bead and some extra capacitors near to the USB connector to further reduce electrical noise issues.

Acoustic noise

In the previous update, I mentioned that our PCBs were emitting some audible noise which was proportional with the number of LEDs enabled. Robi also looked into this issue and the solution has several steps to it.

First, throwing more capacitors onto the PCB drastically reduces electrical noise, which in turn also reduces the piezoelectric effect responsible for the audible noise.

Second, the ceramic capacitors will be placed in a way that they won’t enforce each other’s vibrating effect.

Third, we’ll use higher value resistors for the R_EXT pins of the LED drivers because the current consumed by our latest prototype with all LEDs enabled is higher than the maximum current the USB connection can provide. Lower current draw will translate to lower noise, and given the logarithmic sensitivity of the human eye, the brightness difference will hardly be noticeable. LED lifespan will also benefit from this change.

We’re fairly confident that the above fixes will resolve every electronic issue. Our next PCB should be ready to pass EMC tests!

Bootloader

Santiago has been extremely busy with his work at NXP (now Qualcomm). So much so that he’s had hardly any time for us, but luckily, he managed to spend a whole weekend on the bootloader recently. Because of his efforts, the master bootloader is working! This means that it’s now possible to update the firmware on the right keyboard half via USB.

But that’s only half of the story. The other half involves implementing the proxy which will route the firmware of left keyboard half and modules via the right keyboard half. If everything goes well, Santiago be able to allocate enough time to get this done soon.

Our new contributor

I briefly mentioned my friend, Róbert Csordás, above. He has been a huge help in solving the electrical issues of our design, so this is the part where we express our appreciation.

He hasn’t only helped with electrical issues, but also improved the firmware in a lot of ways. He implemented a QWERTY layout, then made the communication between the keyboard halves more robust.

Robi is already a full-time UHK user. His only wish is to receive a plastic case for his prototype, so that the bare solder joints of the PCB won’t scratch his desk. We’ll make sure to send him a final UHK with all the bells and whistles as soon as we can.

Thank you so much, Robi!

Project progress and schedule

Right now, the steel guides, the feet mold, the rubber mold, and the magnet counterparts are being manufactured.

The molds of the case and the steel plate cutting tool are being adjusted to meet our manufacturing constraints. This is planned, but it will take a little longer than expected.

The PCB is being redesigned as described above in order to minimize electronic and acoustic noise. It will be ready by the end of the upcoming week, and then we’ll put it through EMC tests in December. We should have the necessary certificates by that time. We’ll launch a prototype run for the PCBs in January and start our first full production batch in February.

By the time the boards get manufactured, we’ll have all the parts and packaging in our warehouse, ready to be assembled and shipped.

We can assure you that everything happens according to the grand plan, but many things take longer than expected. We know how much you would love to have a UHK by the holidays, and we’re doing everything we can to deliver as soon as possible, but we can’t reasonably expect to ship sooner than February.

We’ll keep these updates coming with clockwork accuracy, so you’ll be aware of our progress at all time. Should you have any questions, we’re always here for you.

Thank you for your continued support, and we’ll talk to you again on 2016-12-15.

40 Responses

So no "by the end of December" anymore, then, huh?

I'm afraid we missed December, indeed. We're sorry about the delay, Trevor.

and again +2 month...

Yes, this means +2 months. We're getting very close, and will do everything we can to hit the new delivery date.

Where do wood rests come from? Will they be ready in February?

Every parts of the palm rests are manufactured and assembled here in Hungary. We're confident we'll be ready with them by February.

Have you thought of posting the progress on FB more frequently?

We have considered it, but finally decided to rather write montly updates to minimize our overhead, and allow us to focus on development and manufacturing as much as possible. We may post more frequently on social media as we march toward delivery, but we rather wouldn't make any promises about it yet.

another delay :(

Sorry about it, Noam! We make sure it's worth the wait!

So, Bob Cochran was right after all (https://ultimatehackingkeyboard.com/blog/2016/08/18/updated-delivery-schedule-and-a-bonus). But I'm even thinking it will be somewhat later, because of holidays, Chinese new year, February is a short month, as a small company buy small amount of parts can be hard (low interest of the supplier), holiday of suppliers etc. And the first set of production-runs will never run as expected.

So I'm betting on late March.

But keep up the good work, don't post to much, just focus on getting the product into the hands of the backers (I trust you, that's why I bought the UHK instead another one). You are a startup with young people who experiences in real live what it is to develop a product and get it into production :-) But I can assure you, it's a fantastic experience even with all the delays.

So if people sounds a bit angry, don't take it to much, they have to understand that it's not a big company behind this with a lot of people and lots of experience. If you want to post more information, please hire another person to do that and call it marketing.

Great points, EdbO.

We'll try order every part from China before Chinese new year, but the first production runs are known to be problematic, indeed. We'll do our best!

We don't have resources to hire a PR/marketing person at this point, but we're thinking about posting small news-bites on social media every now and then. That shouldn't take too much time.

Also, thanks for your encouragement, and support!

What about a non-backlit version in the future?

It will surely simplify things a bit, along with electical noise, etc.

Do you mean providing a backlit version in the future? Right now, we only provide a non-backlit version (even though it's quite easy to upgrade to a backlit version by anyone with a soldering iron and several dozen LEDs). The plan is to future-proof the design, so that it will be much easier to release a backlit version later.

We'd have to address acoustic and electrical noise anyways because the LED display is driven by one of the LED driver ICs and to comply with the USB specification.

Aww, 2 more months

But besides that, I am sure it is worth the wait!

Keep up the good work, and thanks for the updates :)

Thanks for your support, Kim! We make sure it's worth the wait!

Hey Lazslo,

Thanks for the updates and I appreciate the attention to detail you guys are putting into the product. However, since the UHK is getting pushed back AGAIN I would really like to put my name down as someone else that wants more updates. One update a month is just too long for me. Realizing you guys already have your hands full I think a great compromise might be two smaller updates a month. This would alleviate some of my patience issues and I think it would also help people feel better if/when you guys run into more issues that delay the product. Since two updates would give slightly more transparency it will be an easier pill to swallow because everyone is more aware of what's going on. Just my opinion of course, but please consider it.

Thanks UHK team.

Hey there ZestfullyClean,

Your voice has been heard! How about posting small news bites on social media every now and then? I'm thinking about a one-liner along with a picture. That'd be minimal effort on our part, and you'd be better informed.

Hey!

At least you are making progress, right!

I´m so thankful for your status blog posts!

I´m soooo ready for this keyboard!

You should split blog post update in to two part instead!

And at last, an estimate is an estimate... I do believe that you working as hard as you can for making this happen!

Thanks for rooting for us, Johan!

We plan to post a couple of small news bites with pictures on social media between our big monthly updates to keep you in the loop. Let's keep in touch!

One update a month is quite sufficient. My own career involves me in complex projects, albeit not in manufacturing, but still involving delivery dates of very complex products. What we have here is an extremely complex product with a lot of required engineering. Generally speaking, I do see projects that run well behind schedule. When that happens, the project executives want to exert yet more oversight and the method they choose is usually to require more frequent "updates". This often causes the project technicians to spend much more time providing the updates being demanded. If they are spending their time writing updates to satisfy the executives, they can't spend that same time grappling with technical issues. The "update" time is lost forever. Requiring more updates often causes the project to slip even further behind schedule as a result. I think that one monthly update, as is being done here, is quite sufficient. This project team in my opinion is very honest and open about the challenges being encountered. It is no easy thing to mass produce a product like this to a high quality standard. What you are seeing are some of the challenges they are hitting. Probably there were many lesser technical issues that they overcame and felt were not worth discussing in the monthly updates. I think you are seeing an extremely normal product development and delivery cycle here. It will be produced and delivered. The UHK team will ultimately go on to other projects, and now having some real-life experience with delivery schedules, will likely consider the schedule more carefully for future efforts...but for new, complex projects there is always going to be some lateness. I suggest that others should keep the faith and let the project team continue their work. Whipping them for their honesty achieves nothing.

HEHEHE, you've got the same experience as I have in my career as mechanical engineer. Once a project got delayed, we have to spend more time on "communication" and "transparency" to get the project back on track. But it got delayed even more because of that.

The way to a new (complex) product is never a smooth highway where everything is going well. There are always pot-holes (some are very deep) which you overlooked and traffic jams at the supplier.

So on 2016-12-15 the next update please :-)

Hi again, Bob!

Every word of yours oozes wisdom, and not just now but the previous time, too. It's apparent that you've seen it all over and over again and know what you're talking about.

We have definitely encountered with a couple issues we were unaware about, and some external issues, like manufacturing delays are simply outside of our control. I agree that this vast learning experience we're going through will enable us to estimate the schedule of further products more accurately. But just as you said, I can also foresee that new complex projects, like a bluetooth UHK would take much more time than anticipated.

Keep up your comments! It's a pleasure to read them.

Hi,

Really looking forward to this, no matter how long it takes I'll be buying one (I would have helped fund it even if I knew it would take this long, but I didn't have a job then).

It looks amazing, one of the few kickstarted projects I'm REALLY looking forward to.

Thanks for the awesome work!

Thanks for the kind words, and for considering to support us, Zack!

So this month's update helps me see there are still some tough challenges ahead. The plastic casing has a manufacturing issue. The PCB needs to be redesigned due to electrical noise, and the redesign is going to impact other manufactured parts too. The bootloader isn't complete yet and needs a lot of work.

Given this and the people resources the UHK team has, I think the team deserves warmest congratulations for their work to date, and everyone should be very patient about production of the product itself. It is going to take some time.

There are definitely some challenges ahead, although the tweaking of the plastic mold and the redesign of the PCB should not affect other manufactured parts.

Luckily, the bootloader doesn't have to be written from the ground up. Santiago already ported KBOOT2 to the K22 processor, and he's about to port the blhost proxy firmware too which will route the firmware to other modules. Being a maniac, it has only taken Santiago a week to port KBOOT, and blhost should only take about two days. The trick for him is allocate enough time for us because he's assigned to all the key projects of NXP in EMEA.

Woohoo! Best of luck to you guys. Take care, don't burn out. Hardware is a challenge. Pity there's a delay again but I understand the challanges. Plow through them but take the time needed. UHK!

Thanks for your support WeZzy, really appreciate it!

Please take your time to deliver the best quality possible.. Always start off on the right foot and it will go a long way..

The worst decision a new startup can make is to cut corners and push the product out of the door as soon as possible..

Quality matters most to me, so time is secondary here.. The updates are showing me that I will get the keyboard eventually and that is good enough..

Hi Stanley! It's great to see that we share the same values. Thank you for your understanding and support!

Thanks for these monthly updates, I really appreciate them.

One question: will there still be a foam (or other soft material) option for the palm rests? I really don't think I would like wood, both how it looks and feels.

Hi Jeroen,

We don't plan to make other versions of the palm rest, but we're pretty confident the current version will look and feel excellent.

I understand, but I really don't want wooden palm rests. Can I cancel my order for them?

I'm sorry that you don't like wooden palm rests, Jeroen. Please shoot an email to orders at crowdsupply.com to cancel your order of the palm rests.

What are the specs for the LEDs you added for the backlighting?

For the time being, we used VLHW4100 LEDs, although we believe the IS31FL3731-SALS2 LED drivers can deal with pretty much any T-1 LED we throw at them.

Awesome, thanks! I love the attention to detail on this project. This keyboard looks to be incredible. I can't wait!

I felt the wait is a bit too long especially when I saw this recent product on Amazon:

Mistel Barocco Ergonomic Split PBT Mechanical Keyboard with Cherry MX Blue Switches

https://www.amazon.com/dp/B01KN6VEYG?m=A3VFIY9T3ATK6N&ref_=v_sp_widget_detail_page

If I didn't pre-order UHK in March, I would definitely buy the one from Mistel and start to use it two months ago.

We're sorry about the delay, Lay. We're doing our best to ship as soon as possible, and will be keeping you in the loop in the meantime. We don't hold your money hostage, so you have the opportunity to cancel your order, although we hope you stay with us. We'll make sure the UHK is worth the wait.