Hi there, and welcome to our monthly status update! Let’s warm up, and see what’s been happening in UHK land these days.

Mold meetup

Our mold-making contractor let us know that they’re done with the molds of every plastic part, so we made a second trip to Serbia to check them out.

The best part of the meeting was snapping together the top and bottom parts of the case, and hearing the satisfying click sound, meaning that the parts fit together accurately. This is not something we’ve ever heard when trying our 3D printed prototypes.

Putting the LED display into the case was a similarly elevating experience. These parts are so precisely fabricated that they look like a single part from the outside.

Having all of the plastic parts injection molded is a major milestone, but it’s not the end of the story. Aesthetics will improve by tweaking technological parameters of the molding process. This is fully expected in the world of manufacturing, and our contractor is working on them.

Inserts

Having the injection molded parts and the final inserts in his hands, András put the inserts into the case and tested them.

As it turns out, even 16 kg can't pull a single insert out. We're about to order 16K of these little guys.

Guides

What does one do with 80 kg of stainless steel rods? Turn them into 16,000 guides to hold the keyboard halves together!

As you can see, we have already ordered the raw material, and we’ve also found a local manufacturer who will get the job done.

Palm rests

In our previous update, we published a picture of the wooden inlays on the palm rest but weren’t sure about the final color. Now, we’re experimenting with a couple of options.

Let me introduce you my mother, Klára Monda, who just happens to be a furniture painter folk artist. That’s right folks, the UHK is becoming a family business! Having more than 40 years of experience behind her, she’s more than qualified to dye and lacquer the wooden parts of the palm rests.

So far, a dark brown “walnut” dye seems to be the best match for the UHK case, but we will also give a graphite color a try soon. We’ll keep you posted.

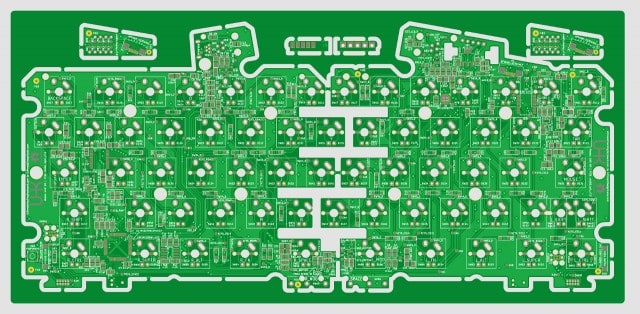

New PCB

10 of our 7th generation PCBs are being fabricated at Eurocircuits and will arrive at any moment.

These PCBs should fully resolve acoustic and electrical noise issues and contain lots of small improvements. They’re heavily optimized for manufacturing, boast 100% test point coverage, and also include little touches like the UHK and OSHW logos. As soon as they arrive, I will assemble a couple and meet Robi to test them thoroughly.

5 of the prototype PCBs will directly go to our PCBA contractor. They’re eager to do a first small prototype run so that they can create the tooling for efficient mass production.

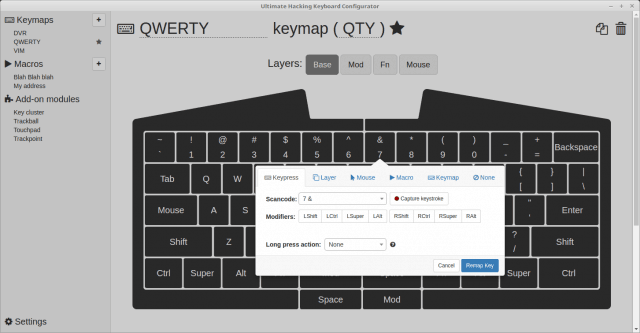

Agent

Józsi and Nejc have been working very hard on Agent. As the fruits of their labor, Agent has become far more polished than ever before.

You’re welcome to check out Agent in your browser to see for yourself. Click on any key to see the key action popover appear. Then associate an action of your desire, and see the new action displayed on the key. Then rename a keymap, or its abbreviation, set it to default, duplicate it, or delete it. All these things should work smoothly now.

We still have a lot to do, but Agent already resembles the final application pretty well, and we’re making rapid progress.

All hail the Input Club

Jacob Alexander of the Input Club has been doing some mad science lately. He has created the The Comparative Guide to Mechanical Switches by doing one-of-a-kind mad science. Lucky for us, Kailh switches were rated among the top contenders, so it looks like we’ve made a great choice. We’re extremely impressed by Jacob’s work.

While speaking of the Input Club, let’s give credit where it belongs. When porting the UHK to ARM and searching for the best microcontroller and LED driver we could use, we checked out their open source keyboard designs, and picked the same ARM processor and LED driver that they used.

Later on, we upgraded to a more powerful processor of the same family, and created our own schematic, PCB, firmware, and configuration application, but still, they have definitely affected our design in positive ways, so mad props to them!

More frequent updates on social media

Lately, some of you asked for more frequent updates and we’re glad to comply! Since our last newsletter update, we published 3 updates on social media. The plan is to post updates on a weekly basis on social media. You’re welcome to subscribe to our Facebook, Twitter, and Google Plus channels to for even more UHK goodness.

And that was it, folks! We’ve arrived at the end of our December update.

Let me take the opportunity to wish every one of you Merry Christmas and a Happy New Year on behalf of the whole UHK team! We’re so happy that you guys are on board!

Talk to you on 2017-01-19.

33 Responses

Were those mouse buttons 3D printed or made in the new molds?

The case buttons were injection-molded in a previous run, hence their differing color.

Sweet! It finally comes together with nice snaps :-) . Hopefully everything will be all right with the new PCBs. Keep up the good work, but don't forget to take some time off, especially with this time of year.

Thanks EdbO, we'll take some time off for Christmas. But not too much! :) Happy Holidays!

Can't wait to see it fully assembled :)

Neither can we! :)

Updates to this blog are one of my favourite reads. Thanks for all the thought and care at every stage and sharing it with us. It's looking beautiful.

It's our pleasure! Writing this blog is a labor of love, just like the whole project. Glad you like it.

Ah. That time of the month again. Here, we go, here's my monthly cheer for you guys: WOOOHOOOO. Have a nice holiday and best of luck snapping them plastic thingies together! :)

Thanks WeZzy, working on it! :) Have a nice holiday you too!

What will be the final plastic surface texture for the main visible surfaces (= not the back nor the interior)? Will it be closer to matte or closer to sandstone?

I'd say closer to matte. The picture which shows the back of the UHK with the insers should give you a good idea. It's pleasant to touch, and doesn't attract dust.

Hey Team, great progress! the plastic pieces look really slick. Are you guys planning on releasing more than 1 type of palm rest? A wood texture doesn't go well with my desk, it's too "rustic" for me, I was thinking of something more on the lines of the previous renders that you had https://ultimatehackingkeyboard.com/wordpress/wp-content/uploads/anodized-aluminium-palm-rest.jpg

Hey, Pablo! We only provide a single palm rest type / color, but we may end up picking a graphite color which may go well with your desk. I suggest you to wait a bit more until we finalize the design and publish some pretty pictures.

Reading the blog every month is one of my favourite things to do. Seeing the keyboard coming together part by part and you guys trying to keep the quality at a very high level, makes me happy of my decision to order one. BTW regular updates on twitter is appreciated, take more snaps and share them please :)

Glad you're happy about the additional social media updates! We'll do our best to keep them coming! :)

Thanks for the updates in social media! It is really great to follow your process and progress!

Glad you like the updates, and happy to share more!

The updates on social media were cool. Good stuff guys.

Will the palm rests be screwed or glued? I'd like the options presented by screws, just so I can, if I want, make replacements in other woods and not have to employ destructive methods to change.

According to our evil plans, the palm rest will be screwed. Nondestructive methods for the win!

Does it come with backlighting for the keys ?

Not yet, but we plan to offer a backlit version later. In any case, one can solder LEDs into the current version and backlighting will work, but the current keycaps are not backlight friendly.

If I order one today (Jan 3, 2017) when is the earliest I can get this keyboard?

Hi Prabath! The earliest delivery date is the end of February. Thanks for considering to support us!

I'm very tempted to preorder this, but I'm wary of first production runs and some 200 dollars is a large investment for a student. The sensible me tells me to hold out until a few months after release so you can work out the kinks, but I really do need a split keyboard for the ergonomics (keeping my wrists straight is... uncomfortable). I also love the low-key design, very clean.

In either case, I'm rooting for you guys, my arms need you to succeed, and I'm always excited for your updates.

I understand your hesitation, Simon. You're welcome to wait until the first reviews, so you will be able to order with confidence. Thanks for rooting for us!

I think this is an excellent product, and there are a couple of reviews online you can check it out. I just ordered one. I have tried almost all the split keyboards out there, there are some good ones, but UHK looks like they understand the key points of a split-keyboard. $200 is a little bit too much, but if you look at what's on the market, the UHK price is not that bad. What they need to do is, add some eye candy modules such as backlit keys.

Thanks for the nice words, Prabath! We plan to add various extra options to the base UHK model including backlights. No ETA on these options yet, though.

Thinking about the wooden rests, over time what would that look like with normal wear and tear? Thinking about how my current keyboard caps have rubbed for the keys I use the most, same with my mouse where the matte paint has rubbed off where I place my fingers on the mouse.

Does the colour go deep through the wood or is is just surface layer stuff?

The color of the paint goes several millimeters deep within the wood, so it should be pretty durable. The outer lacquer layer may be somewhat less durable, but unlike keycaps, it should be relative easy to refurbish, and it should be less noticable because it's matte.

Hello, and thanks for that great post)

Is there a board that I can buy somewhere to use your firmware for my own keyboard? Like teensy or something?

Hi there! I'm afraid our firmware is not compatible with any other keyboard on the market. We use a similar processor in the right keyboard half as the Teensy 3.x boards, but our toolchain is totally different. Also, we use a different processor for the left half and modules which don't have a Teensy equivalent.