Another month has passed, and so it’s time for our monthly status update! This one will contain a bad bit of news, a good bit of news, and lots of news bites on our progress.

Updated delivery schedule

Over the last few months, a lot of you have been giving positive feedback on our progress and appreciated the detailed updates. According to our Crowd Supply campaign page, the goods are expected to ship at the end of September.

We’re trying our best to deliver on time, busting our ass day by day, usually even on weekends, and still, it’s quite apparent that we can’t meet this deadline even if we bend over backwards. So the delivery schedule needs to be revised:

- The keyboard and palm rest are expected to deliver by the end of December

- The modules are expected to deliver in April 2017

Please let us explain the reasons.

Our April delay that was caused by our previous bank (which we abandoned forever) has definitely contributed to this one, as it caused a lot of overhead, and we could only pay to our mold making contractor in a delayed manner.

Another reason is design delays. We have just finished the design of the feet and the palm rest. Getting the design right has definitely taken longer than expected and now the molds of the feet are about to be made. As a rule of thumb, we rather take the time to get the design right than to rush things and end up with a mediocre product.

We have to focus on the core keyboard first and implement the modules afterwards. So the mold of the modules will be created right after the mold of the keyboard. We will pay the extra shipping fees because of the separate shipment of the modules. That’s the least we can do.

We’re running things in parallel as aggressively as we can to hit our updated schedule. For example, a mold of our special keycaps just got ready in Taiwan, the mold of the case and the cutting tool is being created in Serbia, and our contractor for the LED display has just started to work on their mold.

We’re very sorry for this delay. We understand that you can’t wait to put the UHK under your hands and waiting sucks. We’re asking for your patience and to remedy the situation a bit we’d like to offer something, which is an...

Anodized aluminium palm rest

There are plenty of ways to make a palm rest and we have considered various designs over time. One of the candidates involved a beautiful anodized base plate milled from solid aluminium.

[fusion_builder_container hundred_percent="yes" overflow="visible"][fusion_builder_row][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

It was clear from the get go that it won’t be cheap and we were thinking about making it available as a premium product later. But now, it’s our golden opportunity to make up for the delay of the project schedule. So I’m here to announce that we will provide this anodized aluminium palm rest to those who purchase the palm rest pledge before keyboard shipment! The price for the aluminum palm rest will go up afterwards.

Now that we wrapped up the bad and the good news let’s move on to the rest.

Tented UHK prototyped

Since our latest update we got the feet 3D printed, screwed it onto the back of a prototype and shoot a picture of it.

Everything feels right about the feet and we’re satisfied with the overall design. The palm rest is yet to be fabricated. We’ll make sure to show it to you as soon as it gets ready.

The state of the mold

The molds of the bottom cases are complete. This is the left one.

The remaining molds are also in the works, and in our true style, we’ll be posting more pictures as they get made.

Injection molded UHK keycaps

The UHK features two keycap types that are non-standard. One is a concave-shaped, 1.75U, row 4 keycap used by the Mod and Space keys, and the other is convex-shaped, 1.5U, row 1 keycap used by the backspace key.

I’m happy to let you know that recently, our keycap supplier got the molds ready for these keycaps and sent us a couple of samples:

These custom keycaps are impeccable and totally consistent with the rest, just as expected. They put a smile on our faces because custom parts like these are major milestones for the project.

The state of the modules

Not much has been said about the modules recently, so it’s time to share some information on them. We’ve actually made a couple of videos of them in action, so that you can get an idea how the modules feel and behave.

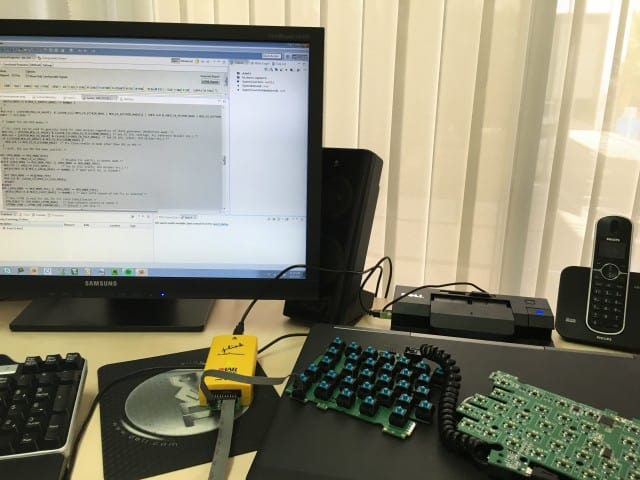

Please note that the plastic case and electronics of the modules are not ready yet. So far, the key components have been chosen so we show you the guts of the modules directly connected to the PC.

If you are curious about the exact ICs that we use inside of the UHK, or in the modules then you’re welcome to delve into our datasheets repository.

As for the number of buttons of the right-handed modules we’re not exactly sure yet but we’re aiming for two buttons per module.

Let’s see what we have!

Trackball module

The trackball module features an ADNS-3530 optical sensor which is remarkably tiny and communicates over SPI. This demo board translates SPI to USB but we’ll use a KL03P24M48SF0 microcontroller to translate SPI to I2C which is spoken by the UHK.

Trackpoint module

The trackpoint module features a sensor of an unknown part number (our supplier signed an NDA with the manufacturer so we don’t know) but it’s remarkably similar to the now defunct SK8702 trackpoint module which features the SK7102 controller. Our supplier only provided an incomplete datasheet to us, which is not a major problem because the module speaks PS/2.

We’ll use the FlexIO capability of the KL03P24M48SF0 microcontroller to implement a protocol translator which will translate from PS/2 to the I2C protocol of the UHK.

Touchpad module

This is an Azoteq ProxSense TPS43 touchpad driven by the Azoteq IQS572 capacitive controller. The touchpad is connected via the Azoteq CT 210 configuration tool to the PC.

Being an I2C device, the controller will directly connect to the UHK. We’ll have to design a custom-sized touchpad, however, featuring the IQS572. Luckily, Azoteq provided a design guide for that.

It’s not a coincidence that I mentioned the name of Azoteq a fair number of times above. Back in the day I blogged that we’re looking for a suitable part, then they contacted to us and provided the most awesome support ever!

Key cluster module

The key cluster module features a couple of keys and buttons which are simple to scan by the microcontroller. The tiny trackball is a Blackberry trackball which uses hall effect sensor along the 4 axis. We haven’t yet hooked up the Blackberry trackball to control the mouse pointer but you can find plenty of videos on YouTube of its various applications. I recommend watching Sparkfun’s video of their trackballer breakout board which explains it in detail.

Introducing our firmware developer

A while ago, we reached out to you looking for a firmware developer. We’ve gotten quite a few excellent applications and please let me take the opportunity to thank every one of the applicants for contacting us.

Without further ado, let me introduce you our firmware developer, Santiago González Fabián from the sunny city of Madrid.

My name is Santiago González and I've been playing with electronics and computers since I can remember, but I discovered the amazing world of embedded systems in the Electronics Engineering Bachelor where I felt in love with 8051 and ASM code.

I've programmed 8 bit and 32 bit MCUs in C and Assembly mainly, and my focus the last 4 years has been the Cortex M world, working at Freescale and NXP as Field Application Engineer trying to solve all kind of issues with Embedded Systems all over Spain, from Automotive to Industrial equipments, from 8 Kb Flash devices toggling LEDs to 2 MB Cortex M7 doing Ethernet, Motor Control and RTOS scheduling at the same time.

Embedded systems are my job and my hobby (Although I also climb mountains in the weekend) so in my free time I look for new challenges in several places (Stack Exchange, HackADay, Electronic Forums...) and that's how I met László and UHK, in my weekly check of NXP Community. After having a look into the project and the open source philosophy behind it, I decided I would love to help if possible. Now the UHK PCBs have arrived to Spain, so I can begin the Bootloaders development :). I cannot wait to start coding!

[/fusion_builder_column][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

Since first getting in touch with Santiago, I’ve exchanged almost a hundred emails with him about deep technical stuff. It’s apparent to me that he’s highly knowledgeable, a truly excellent communicator, and his enthusiasm clearly shows. We couldn’t ever wish for more than that.

The bootloaders of the UHK are a lot more complex than those of regular keyboards (not that most keyboards have a single bootloader to begin with). This is because our design is highly modular, composed of separate keyboard halves and modules, each running separate firmware images. So naturally, we want to enable you to upgrade the firmware of every module over USB with a click of a button.

The idea is that the right keyboard half will run the master bootloader that will directly upgrade the application firmware from the PC. The left keyboard half and the modules will run the slave bootloader which will connect over I2C to the master bootloader, which will in turn relay the firmware image from the host computer over USB.

KBOOT 2 already supports the above scenario, but a fair amount of customization has to be done by somebody who really knows what he’s doing.

Apart from implementing the bootloaders, Santiago will be working on parts of the firmware that require deep knowledge of the Kinetis platform, like the FlexIO based PS2 to I2C protocol translator of the trackball, and such.

Still reading? Then pat yourself on the back because you deserve it! Talk to you on 2016-09-15.

[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

22 Responses

>> The keyboard and palm rest are expected to deliver by the end of December

As expected...

Hi Averrin,

Well, we didn't expect this delay originally but it became more and more apparent and called for an updated delivery schedule. We're sorry about it, and will do everything we can to ship the keyboards as soon as possible.

I'm a bit disappointed, but I saw it coming. Way too less time to get the design and moulds done etc. Can you please make it a Christmas present ;-) ?

But you give the people who purchased the palm-rest a bonus. But what about the people who didn't? What kind of bonus can they expect? The much cheaper palm-rest, a free addon, a bit discount or .......?

Hi EdbO,

Thank you for your understanding! We're working hard to make the UHK a Christmas present!

We agree that we should give everyone a bonus, not just those of our backers who purchased the palm rest. The problem is that we really have to watch our expenses in these early days because tooling costs eat into our cashflow seriously, and we'd rather leave a healthy room for unexpected expenses.

We're thinking about something special for everyone like a thank you note or maybe even better, a schematic drawing in the box. We understand that it's not much but hopefully it will get the message across.

Truth to be told, the aluminium palm rest has been chosen not just because it's a premium item, but because it does not involve tooling. This is very important because tooling equates extra delays and we definitely don't want to introduce any further delays. And we did not mean it as a sales pitch. It was simply a practical, premium offering.

I am a software developer with no hardware design or manufacturing experience. I'm in a project right now where it is essential for me to work with elements written in the C programming language. Unfortunately I have never studied C closely. My project will have some delivery delays -- as with most software and hardware projects, a number of things add up to cause such delays. So I can understand the delays you are announcing. There are many complex processes at work here. So I can be quite sympathetic. In my eyes, your delivery schedule is now becoming more realistic. I think the dates actually need further adjustment. Perhaps the end of February or March 2017 is a better target for the keyboard alone? With "add on" modules scheduled for perhaps August 2017? If you say "December" many people will hope for deliveries in time for their holidays, and that might be a very difficult expectation to handle. It is wise not to back yourselves into that kind of corner.

Hi Bob,

I can see what you mean, and I love your analogy regarding software development. We have chosen December because given the actual status of the project we should be able to hit it. We could have chosen something like March but we doubt it'd be necessary. Also, the earlier the delivery date, the harder we push ourselves, so all in all we think it's a good choice. We are doing our best to deliver for Christmas.

And thank you so much for the sympathetic words!

There is nice video about estimates from MPJ: https://youtu.be/6LERX0pLZfs

Hi Jaroslav,

Thanks for the video! Just watched it and enjoyed it very much. Michael Wolfe must have encountered a lot of shit because the scenarios mentioned feel awfully realistic.

hey guys I wana thank to you, nobody knows how much work is behind this project. Thank you for this great keyboard

Hi Petr,

Thank you very much for your understanding and appreciation!

Still less of a delay than I encountered when I pre-ordered my Matias ErgoPro, and they were an established company that has done this before.

Hi Stephen,

I didn't know that it was possible to pre-order the Ergo Pro back then. The fact that even Matias struggled in this respect surely speaks volumes about the difficulty of hardware manufacturing. We don't want to use their case as an excuse, though.

Hey, I just wanted to chime in to say thanks for being so transparent about the process. I went into this knowing that manufacturing a new hardware product is bound to be full of uncertainty and complications, but I was so impressed by your design and enthusiasm that it was worth supporting. While it would obviously be great if everything went according to the initial plan, I feel like you've been doing a great job dealing with the problems that have come up and keeping everyone up to speed. Crowdfunding is inherently risky, but I trust you guys to make a great keyboard and get it to me as soon as you're able.

Thank you so much, Yusef! Understanding words like yours mean the world to us. We're doing our best to hit our updated schedule.

Is it December yet? Just checking in as I lost track of time... :)

Just wanted to wish you guys good luck. Thanks for the major effort! Can't wait till December! Go produce, produce hard! Wooooooo!

Thanks for rooting for us, WeZzy, we're pushing it hard!

Keep up good work, people. I really do like the way you communicate timely with your customers. This will carry your enterprise a long way over past and potential upcoming difficulties what ever they may be. Other companies should watch and learn!

Thanks for the nice words, Arto! We're doing our best to keep you in the loop.

So February now, as Bob recommended?

Yes, according to our most recent update, it's February. Bob either has a crystal ball, supreme intuition, or both.

When typing (with a text box in focus), can you make the trackball function as up/down/left/right keys?

Similar to how you could move the caret position when typing on phones that had a trackball.

Now, this is an interesting use case! Yes, we can translate pointer movements to cursor keys, although we'll implement more basic firmware features first, but we'll get there eventually. Thanks for the idea!