Hi there, and welcome to our monthly status update!

TL;DR: We’ve pre-assembled the parts of 2,000 UHKs. Things are progressing rapidly, but color-matching plastic parts and pad printing them accurately was more problematic than anticipated. The rejected parts are being remanufactured and are expected to be ready by next week, at which point the assembly and delivery of batch 1 of the first 2,000 UHKs will begin.

We’ve set up a dedicated delivery status page which you can check out to get up-to-date information on how delivery proceeds.

Mechanical issues

It never ceases to surprise us how seemingly mundane things can go sideways, such as color-matching, or accurate pad printing. Take a look at the following picture.

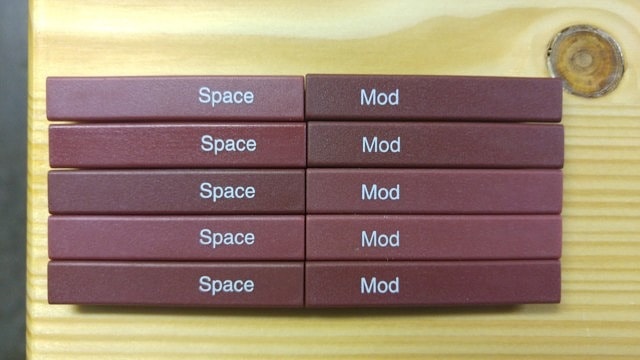

As you can see, the color of these case buttons is inconsistent. This is the first time we molded all case colors, and some mistakes were made due to lack of experience with the coloring agent. As it turned out, this is not the only thing that can go wrong when it comes to the case buttons.

Then we observed that the vertical positions of the Space and Mod labels considerably differ because the pad printing wasn’t set up accurately.

We’ve had our fair share of WTF moments during the manufacturing process. I mean, what can possibly go wrong with seemingly trivial parts like the above? The answer is, as you can see above, a lot. And when one thing goes sideways, the delay of every relevant supplier in the chain adds up, and trivial mistakes can end up costing weeks.

The case buttons are being remolded, and they’ll be pad-printed by the next week, at which point we will finally be able to start up the manufacturing of batch 1.

Setting up manufacturing and fulfillment

As I elaborated in our previous update, all UHK option combinations considered, there are 240 different UHK types to choose from, so we have to track orders individually during the manufacturing process, which calls for a custom manufacturing system. We also purchased a fair bit of related hardware, like label printers, barcode readers, and wall-mounted displays to aid assembly workers.

Recently, I’ve been hard at work, developing our custom manufacturing execution and order fulfillment system from the ground up. It’s surely an unwelcome detour amidst of all our responsibilities, but it’s absolutely necessary, and it’ll give us a competitive edge in the long run. The system is already running well, and we’ll be able to start manufacturing next week. I’ll likely have to tweak it during this month, and afterwards we’ll finally be able to give some much needed love to the modules.

Miscellaneous

You’re welcome to check out the new releases of Agent and the firmware as some improvements have been made which you can benefit from.

Even though a lot of progress has been made since our previous update, we don’t have too much to show besides the above. According to our current schedule, batch 1 will be delivered from March to July and batch 2 will follow very closely. Again, feel free to check out our delivery status page any time if you’re interested in our up-to-date progress, and follow up on social media.

That’s it for now! Thanks for reading this update, and talk to you on 2018-04-19!

10 Responses

Is it too late to change the shipping address? I've just recently changed recurrences.

Hi Dylan, Feel free to change your address at https://www.crowdsupply.com/account - Thanks so much for your support!

The delivery status page is VERY outdated. Please update

It's actually updated. We're about to launch the weekly batches this week or the next.

Any news on the modules? Have not heard from them for a while.

We're knee-deep in launching manufacturing and currently focus all our efforts on it. We'll give some much needed love to the modules right after this madness settles down a bit. We can't wait to work on them soon!

Delivery status still has no updates... Any progress ?

We had to find an alternate pad priting supplier since the earlier wasn't up to par. The manufacturing of batch 1 shall launch next week.

Wow, you thought it would now start to flow with everything going well. Except ... :-( very very sad. But it's a learning process. Do your suppliers have quality checks in place? These things had to be spotted very early in the process. And because of lack of experience with the colouring agent should have warned them to keep a close eye on production.

So don't trust your suppliers too much (don't believe their nice words) and stay and watch them closely. Even ask them many times to send samples. The first time they everything right but then ...... it's going downwards.

Oh, don't get rushed by people starting to scream about delivery times and status updates. They should understand that writing updates slows production down because you cannot be at two places at the same time. So keep going and after the production, back to the drawingboard for the addons :-)

We try to foresee these issues and prevent them from happening as early as possible, but in many cases it's less than trivial. In this case for example, the supplier provided good samples and then it failed when it came to mass production. We could have asked for more samples but mass production is quite a different ballgame than samples, so it'd have surely added to the delay without adding too much assurance. Luckily, our new pad priting supplier does seem to care a whole lot more, and András will personally supervise them in the beginning of the production run to make sure nothing goes wrong this time.

We definitely won't rush it. :) Luckily, the vast majority of our backers understand this quality-first mindset.