Hi there, and welcome to our monthly status update!

TL;DR: All of the keyboard molds are finalized, and the plastic parts for the pilot run are ready. The PCBs of the pilot run are also ready, and waiting to be assembled. We’re waiting for TÜV to certify our design, and then the PCBs will get assembled. The printing factory is nearly ready with the UHK and palm rest boxes. We need about one and half month to start delivering batch 1. Please see the end of this update starting from the “The state of the pilot run” section to see why.

You can always check out the expected delivery date and update your shipping address on your Crowd Supply account page.

Mechanical parts

We’ve been tweaking the molds for seemingly forever. This process is usually extremely time-consuming and involves numerous iterations, especially for high quality plastic parts like the cases of the UHK. Thankfully, we’ve arrived at the end of this journey by manufacturing the top case parts, which were the only missing parts.

Of all the mechanical parts, only the baseplates of the palm rest are left undone. We weren’t completely satisfied with the coating of the latest samples we got, so we asked for new ones featuring three different kinds of powder coating.

We agreed that the middle, fine textured sample is the one to go with, as it most closely resembles the texture of the UHK case. The base plates of the pilot run are being laser-cut and they’ll be powder coated in a couple of days.

These plates will conclude the manufacturing of every mechanical part. Finding all the suppliers of the mechanical parts, and coordinating the manufacturing process has been an enormous undertaking for us as a small company, and we’re delighted to see that it’s coming to an end.

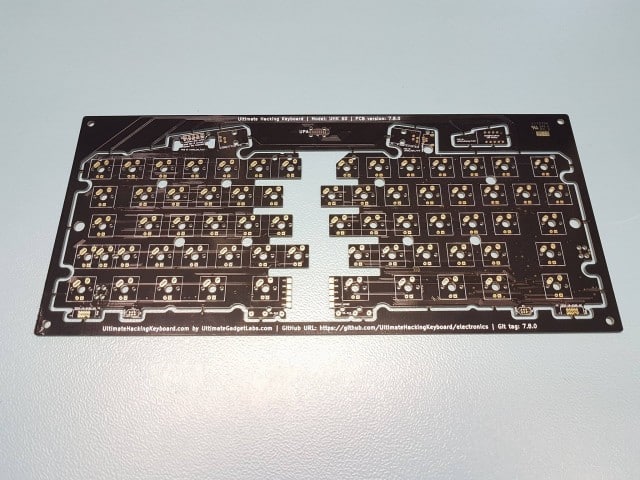

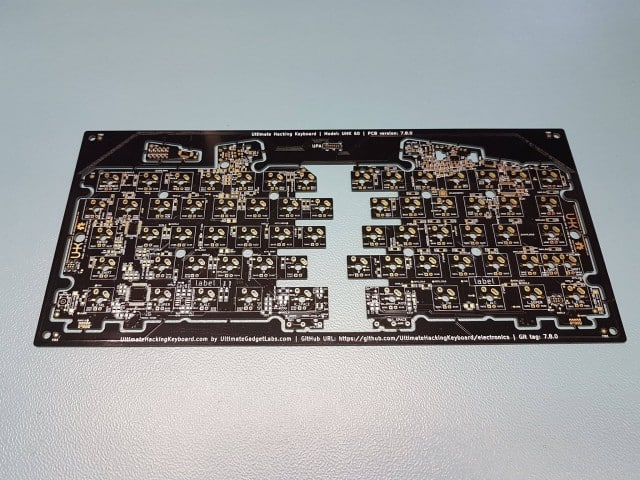

Pilot run PCBs

The 50 PCBs of the pilot run are ready, and waiting to be assembled.

Board assembly will start as soon as we receive the FCC and CE certifications from TÜV. Actually, the UHK may already be certified, we just haven’t heard of it because our contact person at TÜV recently quit. Now his boss is our new contact who is very busy, but nevertheless, he promised to get in touch with TÜV Netherlands and sort things out by the end of the week.

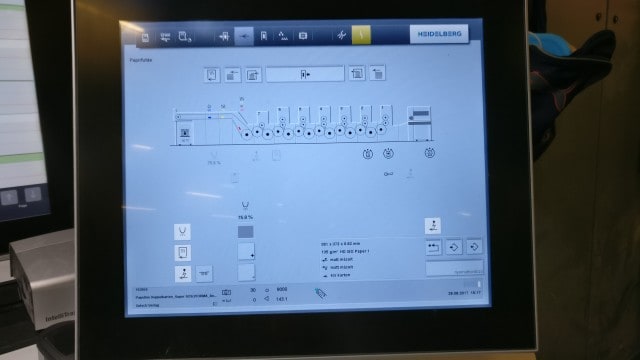

Printing the boxes

We’ve been in the printing factory lately, watching as the sheets of the UHK packaging as they get printed. I didn’t expect anything fancy and boy, was I wrong! The Heilderberg Printmaster printing press which was used to print the UHK packaging is a monumental machine and it was quite a sight.

Packaging is not the meat of the product, but we do believe that it creates an impact, and we don’t like to leave any stone unturned, so we’ve put quite an effort into designing it. Hopefully it’ll show when you unbox your UHK and palm rest.

The state of the pilot run

We’re very close to assembling the pilot run PCBs, and sent out the pilot run surveys to the 50 participants recently.

Outstanding issues:

- As mentioned above, we’re waiting for TÜV. As soon as the UHK PCBs get certified, we’ll commence their assembly. This can happen in days.

- Also mentioned above, the base plates of the palm rests are being manufactured and then powder coated. These should be ready in a week.

- We’re waiting for the UHK boxes, the palm rest boxes, and the back stickers of the UHKs. The printing factory should send the goods to us in about a week.

- The case buttons of the UHKs have to be pad printed. We’ve received a couple of samples from a Hungarian company that had numerous issues. We found another, nearby company who will likely get the job done well and quickly, possibly in a week.

Once the above issues are resolved, assembling the pilot run UHKs will happen in a matter of days, and production speed will ramp up rapidly as we gain more experience regarding the assembly process.

The remaining 1,950 UHKs of batch 1 will follow quickly after receiving some feedback from pilot run recipients.

Given that the pilot run has yet to be sent out, then we have to gather some feedback from the pilot run recipients, and then assemble the next batch of PCBs, we have to push the current delivery date by one and half months, at which point the delivery of the remaining items of batch 1 should start. This brings me to the following point...

Some words about delays

Some of you are growing impatient due to the number of delays that have been introduced over the lifetime of the project. This is understandable, and we couldn’t be more eager to ship sooner. I’d like to elaborate a bit on why it’s taking so long to deliver.

You could see several bullet points in the above section, each involving at least one supplier of ours. We have dozens of such suppliers all around the world (mostly in Hungary, and some in Serbia, China, and Taiwan), and each of them was chosen from numerous suppliers.

For example, I contacted about 30 suppliers for the LED display alone, then chose one, and then exchanged about 200-300 emails with them, got a couple of samples, dealt with customs quite a bit, and all this resulted in the current LED display. And this is a single supplier!

András and I are running this show, two guys from Hungary. I work more than 300 hours a month solely on the UHK, and András is doing his fair share too. The only reason we don’t work more is because we can’t without flat-out burning out. We could add more workforce and experts to the project, resulting in faster progress, but they’d cost a lot of money and we have no room financially as custom tooling and starting and maintaining a supply chain and manufacturing capability is awfully expensive.

Speaking of finances, we’re extremely conservative. Full disclosure: I earn $2 per hour, and András earns $0 while working on the UHK mostly and in his own company part time. The vast majority of the money we spend is on manufacturing and R&D. We realize it’s your money and trust that you gave us to make this project a reality and we’re doing everything within our power to make this a success.

We could simply go to an OEM in China or Taiwan and use their resources to fix many of the issues we’ve encountered, but we’ve made a conscious decision to manufacture the UHK in our home country. The reason being that this way we can directly oversee manufacturing and QA without camping all the time in Shenzhen, and we can be more nimble in the long run, after going through the initial formidable hurdles of starting up all this.

I should also add that the UHK is not exactly an average keyboard, and not just a split keyboard, but a split, modular keyboard that is extendable with modules, which is something that, according to my knowledge, nobody has ever done before. The overall complexity of the project is quite staggering from a mechanical, firmware, electronics, and software standpoint compared to an average keyboard. In a couple of aspects, it’s the most complex keyboard ever made.

It’s also worth mentioning that we’re unwilling to make quality compromises, which also adds to the delays. Among many things, this has made the molds especially time consuming to make and refine.

When we announce a delay, it’s not because we were intentionally keeping quiet about it previously. It’s rather because of some unforeseen issue, like a critical supplier underperforming, a design issue that we couldn’t foresee, a supply chain issue, or virtually anything else we couldn’t think of previously. Very often we have to deal with these as we encounter them, and we always try to do our best. The road will eventually smooth out, but only after hitting every bump imaginable.

So, this is the long and the short of the situation. We’re really pushing it hard guys, and want to make this the best keyboard humanly possible. Let’s get there together, even if it takes longer than anticipated!

Thank you for reading this update! As always, we’ll be keeping you updated on a monthly basis via our blog and newsletter.

Talk to you on 2017-10-12!

20 Responses

Great work guys, its so hardcore project - i've never known something like this before - even if there are delays - i believe it's worth to wait. Heroic workload Laszlo, man, you're tough guy haha :) Thanks for frequent facebook updates - that helps stay calm and waiting;)

I believe you guys are doing a tremendous job. I absolutely love to read the progress posts and see how the process works and how it plays out. Don't burn-out, take care of yourself. As far as I know this is the first product you're trying to bring to market and to me it looks like, even with the set-backs, you are doing a great job. The end is in sight, hang in there, I'm cheering on the sidelines for you guys! Woohoo.

P.S. That Heidelberg Speedmaster is indeed a monster, the sound it emits is like a heavy industrial techno track :)

While I would love to have my UHK now, and I'm sure you've gotten a lot of flack for the delays, I think most of the backers for this project knew that they were backing a next-level product, not just a "nice mechanical keyboard. The communication, progress you share, and your absolutely outstanding attention to detail and quality control make the wait bearable.

I recently received the result from another crowdfunding campaign that initially looked promising, but ended up delivering a shiny...but utterly worthless...product. You hear it again and again how inconsistent these campaigns are...usually the hype ends up being the product itself. Professional marketeers sensing an easy buck by abusing people's faith in something unique or next gen. The reason UHK restores my faith in crowdfunding is because I see your passion in this idea. You understand that some of us have longed for the perfect user interface for our PC's and various computing platforms, and decided to take matters into your own hands. The UHK and your campaign, communication, and community will be the gold...nay...the double-shot injected molded gold...standard for which I will compare all future campaigns and products.

You have made a life-long customer by proving you are more interested in doing things right and satisfying the need we all have...not by promising the moon and stars and shipping shiny, but useless, junk.

I will gladly be purchasing a second (or maybe more) keyboard in the near future...once I get my first one. ;)

Thanks so much for your encouragement and tremendous support, guys! It means a world to us! With backers like you, we can shoot for the moon, reach it, and go beyond.

I too am looking forward to mine. From where I am, I have a suspicion that the second batch will sell out no later than shortly after delivery of the first batch, if not once the pilot run gets into people's hands and demonstrates that the quality lives up to the hype (which I'm pretty sure will be the case). It probably isn't a bad thing for you that people will still be able to get more at the pre-order price after trying the one they already bought. I'm fairly likely to do so myself.

Nice, I got selected and signed up for the pilot run .... Can't wait to get the UHK in my hands! But I'm also feeling a bit embarrassed because of the $2/hr salary :-( The organization I work for has also delayed some projects with more then 3 months, so what is 1 month.

I also cannot agree more with the post above. Please don't start rushing things because it will go very bad. Software-bugs aren't an issue, hardware-bugs are.

And as I said earlier in a comment, people who get impatient don't know what crowdfunding is. You don't buy a product (even it seems like), you give some people (you trust, and I trust you!, you will deliver a fantastic keyboard!) money to help them start a company and develop a product. When everything goes to plan, you will be paid back with the product (way more exciting then getting money back with interest).

There are numerous examples of crowdfunding actions which were going very bad and the "investor" lost all the money. Does anybody see the parallels with the stock-market? On the stock-market you are investing in an already founded / funded company hoping to get more money than you have invested. But you can also loose your money. So impatient backer, please stay calm and let the people at UHK focus on their job, or maybe lend them a hand for $1/hr

So UHK-team, keep the good work! Once you've reached the moon, Mars is in sight :-)

I don't mind the delays, as I see you doing all the same mistakes that we were doing at our company - especially the TÜV certifications - so I know you're on the right track ;-).

I am looking forward to scapping my current keyboard once the UHK arrives, I can wait until then.

Keep up the good work!

Thanks!

Hi Laszlo,

as always, a pleasure to read your updates.

Seeing the PCB pictures i see that it already has the mounting holes for both the LED and matias switch pins, any chance of ordering a key-less unit so i can solder the keys myself?

Hi Den,

So glad you like our updates!

I'm sorry, but we can't provide key-less units. Eventually, we'd like to provide a Matias UHK version, but no ETA yet.

Dang :/

Seeing your progress i'd estimate alps version (if at all) no earlier than 2019.

After trying Matias KB i don't want "cherries" anymore (currently using), alps just feel better. UHK is the only really compact split project i've seen so far. This way i most likely will end up with keyboardio after all, even though it's bulky.

All,

Our blog was behaving naughty recently, and some of your comments may not have been saved. (The WordPress Super Cache plugin was the culprit which we have temporarily disabled.)

Please feel free to resubmit your comments if you can't see them here. We have never ever deleted any comment, only spam.

Thank you for all of the hard work, that you guys are putting into this keyboard.

I am really looking forward to get my hands on it :)

On another note:

Any news on the certification?

Thanks so much for your nice words and enthusiasm, Kim! :)

No news about the certification yet, but it can happen in any time. We'll keep you in the loop.

Have you got the FCC and CE certifications? I saw that you haven't post anything on twitter since last update....

We're still waiting for the certifications. The good news can arrive any time. In the meantime, we've been making progress with the assembly process, and we also got the packaging from the printing factory.

WOHOO!! just read the twitter message ... Certification passed!! Congratulations!!

Thanks EdbO!

Great news! Congratulations! :-)

Hi László Monda,

Your project was quite interesting. you guys are really doing well. Always I would love to read your updates.

Thanks Praddep! I'm glad you find our project interesting. We'll keep the updates coming.