The UHK is durable, super durable - and adding to that innate strength, it’s highly hackable and repairable. Contrary to the attitude of most keyboard manufacturers, we believe that you should have full access (and ease of access) to tinker. Keep reading for a complete picture, or click through to the campaign page for more UHK info.

The UHK differs from usual keyboards in a number of ways. You can tell by starting at the back of the board.

There’s a lot of content here, but I’d like to highlight something specific. The wrench icon:

![]()

It says “Repair friendly”. This is not something that companies usually like to put on their products - and there are a number of reasons why:

- Psychology - The first question that this icon may trigger in customers is, "Oh, crap, is this product gonna break?!". Which is ironic if you think about it, because everything breaks eventually. Nothing lasts forever. To combat this reaction, we put a Durable icon next to the Repair icon because the fact of the matter is that we designed the UHK like a tank.

- Future profit - If a gadget can be repaired, that means that when something goes wrong, you don’t need to just go out and get a new one. As profits and sales numbers are the single most important focus to most companies, most companies are very averse to repairability.

- Extra work - Helping customers repair their gadgets takes support resources. So rather than be creative, and make it easier for customers to conduct their own repair, most companies strive to make repair as difficult as possible.

The above mindset leads directly to the following image:

Image is courtesy of TheConversation.com

But there’s a better way! It’s actually possible to design for repair in a number of ways, and some of ours are pretty unique. We can:

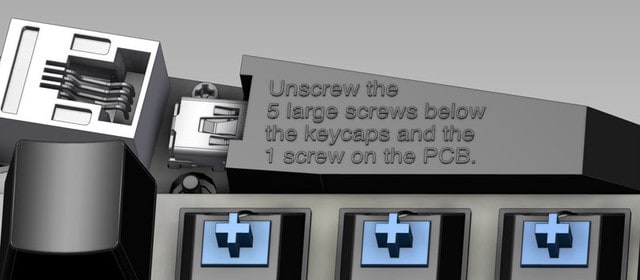

Print instructions right on the circuit board! "Unscrew the 5 large screws below the keycaps and the 1 screw on the PCB" - it’s hard to get any clearer than this.

Print similar instructions on the case.

Display not only component types, but also their value, right on the PCB. See the 10 ohm resistor, and the 0.1 microfarad capacitor.

Little things like the above go a long way, but we’re planning to do even more - like creating a repair manual and repair videos.

In addition, one of our most innovative concepts is to log the number of keypresses for each UHK key-switch. This way, you can keep track of the wear on each individual key as they approach their 50 million keypress lifespan, so you know which will need to be replaced before they even get close.

iFixit said that "Above all, [fusion_builder_container hundred_percent="yes" overflow="visible"][fusion_builder_row][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"][the UHK] is proof positive that even compact, performance-designed, single-purpose gadgets can be designed for repair, from the ground up - complete with repair documentation".

This feedback makes us very proud and assures us that we’re on the right path.[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]