Hi there, and welcome to our monthly status update!

István, our PCB designer, has been on steroids, and he finished the PCBs for every module! The boards are being fabricated right now, and are expected to arrive in a week - at which point I’ll assemble them.

We already showed an inside look of the key cluster module in an earlier post, so this time, I’d like to showcase the right-side modules. I’ll feature three images per module: the assembled version, the half-assembled version, and the latest PCB which is being fabricated.

Please note that the following modules are only prototypes. Their color is not representative, and neither is their surface quality, which will be way smoother once the modules get injection-molded. The color of the PCBs will also differ, as we’ll use black soldermask for the final boards.

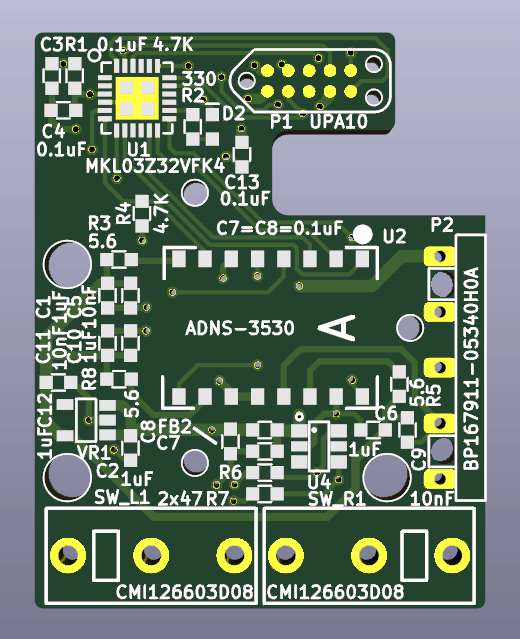

Trackball

The trackball only has a single PCB. It utilizes the ADNS-3530 optical sensor, which happens to be the most compact optical sensor according to my knowledge. The retaining ring can be removed by rotating it counter-clockwise, so one can easily clean the ball.

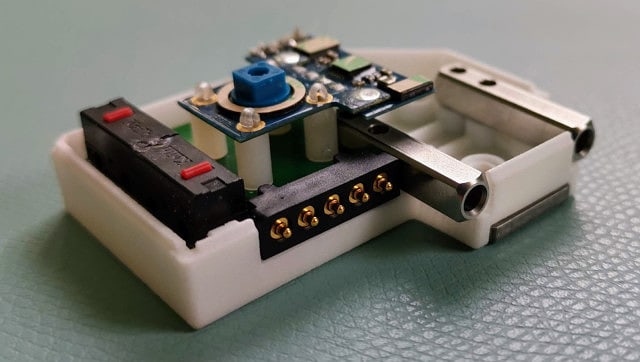

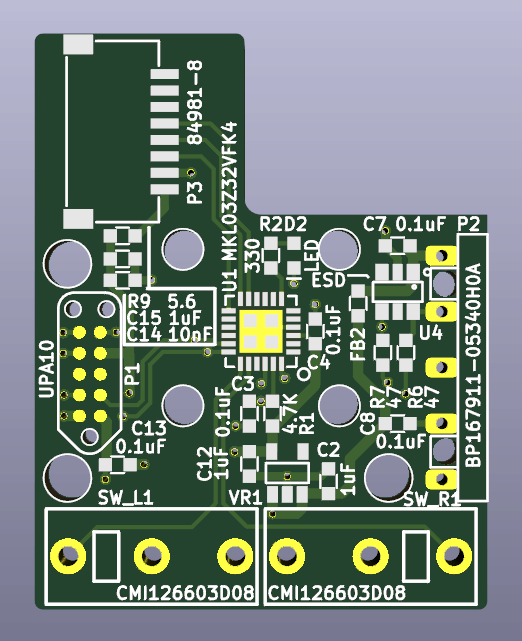

Trackpoint

The trackpoint is composed of two boards. The top board is provided by our supplier and contains the actual trackpoint module. The bottom board is designed by us, and its purpose is to do protocol translation between the PS/2 protocol of the trackball PCB and the I2C module protocol of the UHK.

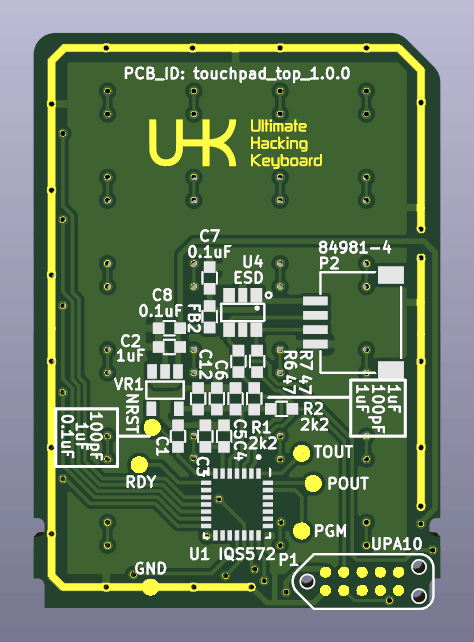

Touchpad

The touchpad module is composed of two boards. The bottom board is a trivial one which simply routes the pogo pin header to an FFC connector, supplying power and data to the top board. The top board does the actual sensing using the Azoteq IQS572 touchpad sensor IC. The top side of the touchpad will be covered by black film.

When I said that that the boards are ready, what I really meant is that these boards should be fully functional. Their design is not set in stone yet, but we expect only very minor changes going forward. Even our mechanical design is fairly advanced and should contain the mechanical features needed for injection-molding.

As I previously mentioned, we don’t have a solid ETA on the modules yet. As you can see, we’re making rapid progress, and we’ll get there, but we surely won’t rush them, as we want to get them right.

Your feedback

You guys keep sending your awesome tweets, and we’re always eager to read and feature them! If you got your UHK, please share your love!

well worth the wait. #GotMyUHK now waiting on the modules to be released from @UltHackKeyboard pic.twitter.com/73cxnXjXLi

— Burhan Khalid (@burhan) August 5, 2019

I am in love pic.twitter.com/VBvnTWnZXc

— Cannïbal @ DEFCON (@Cannibal) August 1, 2019

Yay! I #GotMyUHK from @UltHackKeyboard today, and it seems very promising. Looking forward to master all the layers and never have a reason to leave the home row again. pic.twitter.com/AdjFB3Kwo8

— Mikkel Munch Mortensen (@decibyte) July 22, 2019

#GotMyUHK again. One is for home, another is for office. pic.twitter.com/C3DAewBjFM

— masa kato (@mskt4440) July 20, 2019

An @UltHackKeyboard. I like it so far and might write a review. pic.twitter.com/d1PFvOQRRW

— Neil H. Watson (@neil_h_watson) August 8, 2019

Right, it's an office, there has to be a computer in there somewhere... together with my dearest @UltHackKeyboard. #BitcoinDenShowoff pic.twitter.com/jRh1A8jFHQ

— Stadicus 🌮⚡🔑 (@Stadicus3000) July 18, 2019

We’ll be keeping you updated on all things UHK, and are looking forward to talking to you on 2019-09-10.

4 Responses

I love the progress! Can't wait to order my UHK with the modules! I have a question, would it be possible to have some video demos of all the modules working once they are ready?

Yes, definitely gonna make video demos of the modules in action.

Hey László, you have created a neat product and I would love to order a UHK. Do you have any estimation for the release of the modules? I can't wait for your clever solutions regarding the mouse movements 😅

Hey Eduard, and thanks for the nice words and for considering to support us! We don't have an ETA about the modules yet. Please make sure to subscribe to our monthly newsletter, so that we can keep you in the loop and let you know about the ETA as soon as we'll have one.