Hi there, and welcome to our monthly status update!

First things first, we’ve finally delivered every UHK, including the ones with non-black cases! If you want to order a UHK, possibly with a non-black case, now’s the time. New orders ship in a week.

As for the modules, we keep making progress. Each of the module PCBs has been assembled since our last update.

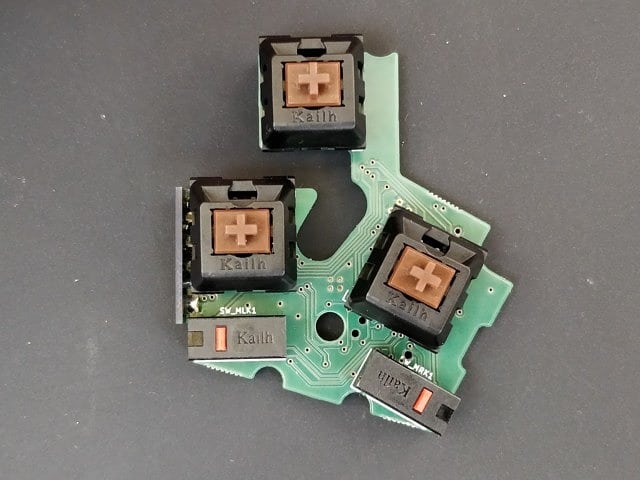

Key cluster

The main key cluster PCB didn’t create any unexpected surprises.

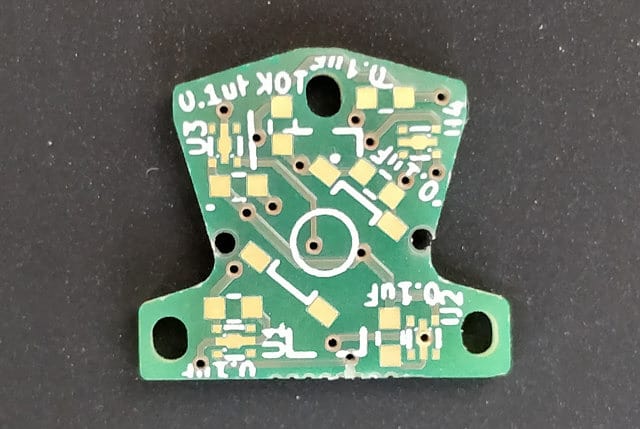

His little brother, the key cluster trackball PCB, however, has proven to be more difficult.

The surface area of this board is merely 1 square centimeter or 0.15 square inch. This is not a whole lot of room for a dozen components, and we can’t make it larger due to the lack of space.

The PCB fab kept rejecting this board because the components were too close to the edges. The only solution was to use smaller magnetic sensor (which detect the rotation of the mini trackball).

We ended up using a sensor with the HVSOF5 footprint, which is ridiculously small compared to the other components we use. I’m waiting for this part, and it’ll be quite an exercise to solder it. But I’m ready for the challenge, and so is my new microscope.

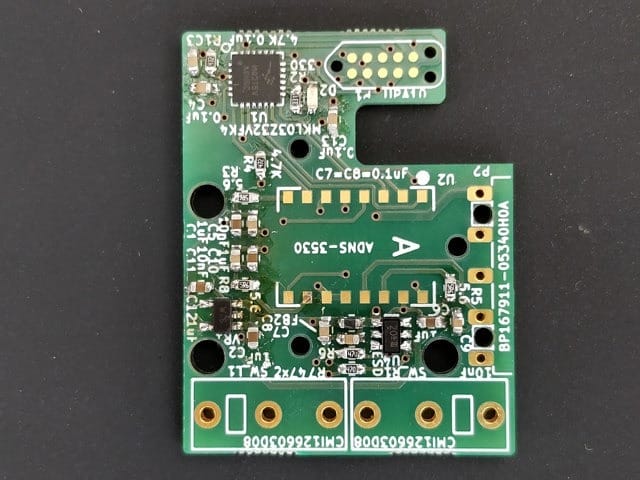

Trackball

The trackball board came out pretty nicely. It’s also completely useless, unfortunately.

While soldering the parts, I realized that the pinout of the ADNS-3530 optical sensors is backwards. The datasheet features the “top side” of the component, but as far as we’re concerned that’s the bottom side. Unlike trackballs, regular mice probably use this component in a reverse-mounted fashion, hence the misunderstanding.

Istvan has redesigned this board, and it’ll be fabbed soon.

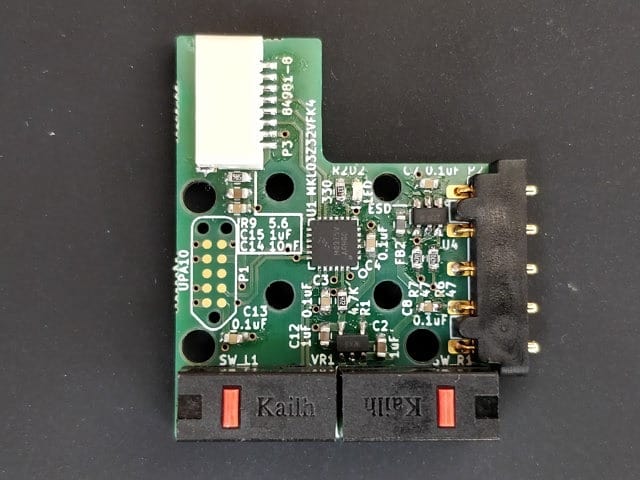

Trackpoint

There’s not much to say about the trackpoint PCB. I haven’t found any issues yet. I think it’ll work well once I write firmware for it.

Touchpad

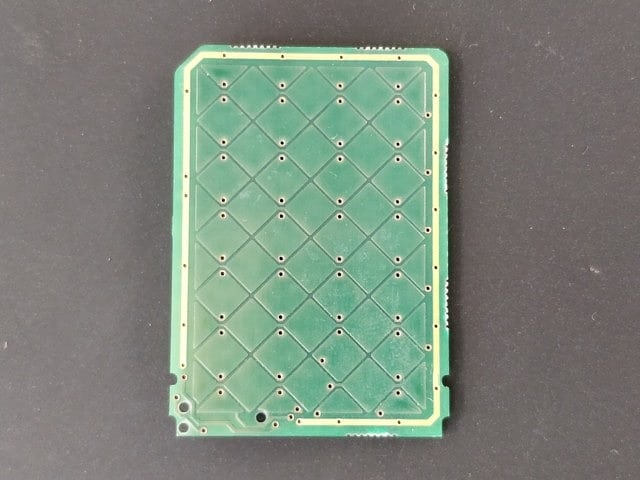

The touchpad PCB has turned out pretty well, too.

This board is hardly our final iteration though. Azoteq, the manufacturer of the IQS572 touch sensor IC that we use, reached out to us and offered to review our design.

They made suggestions on how to improve the ESD immunity of the design, but perhaps even more importantly, they suggested to use a finer pitched sensor matrix to improve the resolution and increase the sensing area of the touchpad.

We plan to implement their suggestions, and then we’ll send some samples to them for further review. The sensor IC is very sophisticated and has a myriad of configuration parameters, so having it tweaked by Azoteq will be extremely helpful. Azoteq provides the best support I’ve witnessed so far, and I’m very impressed by them.

As previously mentioned, we don’t have an ETA on the modules yet. We keep making progress, and we’ll announce the ETA when the time comes.

Your tweets

You guys keep sending your awesome tweets, and we’re always eager to read and feature them! If you got your UHK, please share your love!

I am now ready for some ULTIMATE HACKING https://t.co/7c1atqoVyv pic.twitter.com/MaSukBnYCq

— Jeff Atwood (@codinghorror) September 6, 2019

And now my @UltHackKeyboard has been setup at work, it's just a joy 🤩 (and again thanks to my sweet @neslihanedes for it 😘). Also special @gr8conf cameo in this pic 😉 pic.twitter.com/KFTj5Bbgyo

— Kevin Wittek (@Kiview) September 5, 2019

#GotMyUHK pic.twitter.com/PWgDeBQfHr

— arsdragonfly (@l_dragonfly_l) September 7, 2019

Keyboard upgrade, going dark. @UltHackKeyboard pic.twitter.com/pS5tZFqqdQ

— Stadicus 🌮⚡🔑 (@Stadicus3000) August 22, 2019

We’ll be keeping you updated on all things UHK, and are looking forward to talking to you on 2019-10-10.