Hi there, and welcome to our monthly status update!

TL;DR: We’ve passed both FCC and CE! We’re assembling the PCBs of the pilot run next week and shiping the first pilot run of 50 UHKs around the end of November. We’ll do our best to start to delivering the rest of the UHKs in December, but we may slip to January due to the holidays.

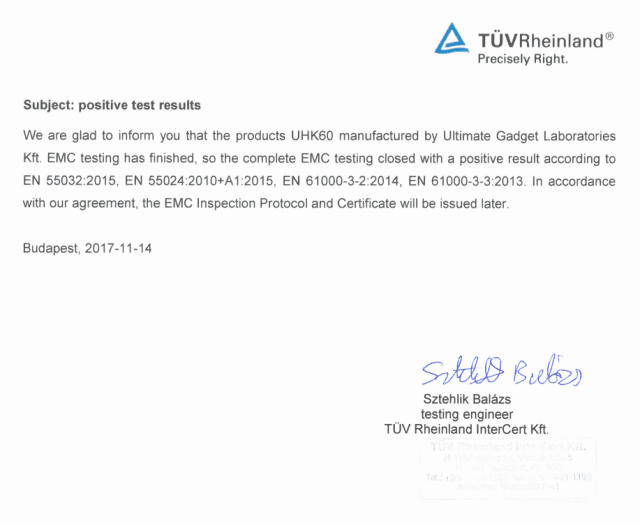

CE passed

We assumed that CE is a piece of cake after we passed FCC so easily, but as it turned out, it wasn’t a walk in the park at all. First, I got a message from TÜV Netherlands saying that we failed CE. They shot one of the UHK prototypes with an ESD gun at the bronze inserts in the back. A discharge of -6kV made the prototype permanently dysfunctional.

Given that FCC was already done by TÜV Netherlands and TÜV Hungary is entitled to certify CE, I called back both prototypes to Hungary. Upon arrival, I investigated the failed one, and saw that the microcontrollers in each half and the FB7 ferrite bead of the right half were fried. After replacing these parts, the prototype was perfectly functional again.

In order to prepare for the next CE test, András fabricated a couple of rubber caps which I glued to the bronze inserts inside of the plastic case to isolate them from the PCB.

Armed with this fix, we went to TÜV to conduct the next test.

Oddly, not only the sealed inserts passed the test, but the non-sealed inserts, too. We couldn’t reproduce the issue that TÜV Netherlands hit, but we found another one.

When Balázs shot the magnet of the right half with the ESD gun, the prototype failed. The lights went out, and operation could only be restored by power cycling the prototype. Even though it’s not a terminal failure, according to the standard, this is a fail.

We came up with an idea on the spot: insulating tape. We stuck some tape to the ends of the right magnet inside of the case which made the prototype hardly ever fail. This wasn’t a sufficient solution because the magnet had to be better sealed. We figured that epoxy should work really well because it withstands 11 kV/mm, and just as assumed, it did solve the issue indeed.

This is the preliminary CE pass for your viewing pleasure:

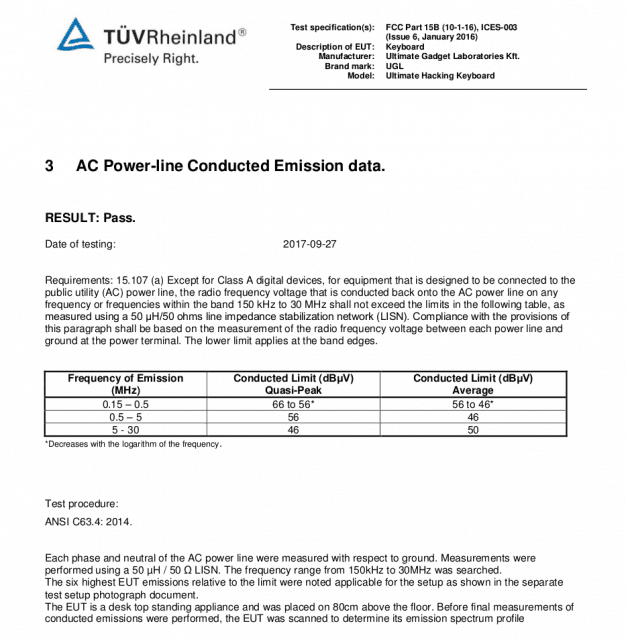

And this is the pass section of the official FCC certification:

Ultimately, we’ll modify the molds to seal the magnets with plastic. ABS withstands 20 kV/mm, so it’s an even better insulator than epoxy, and we won’t have to apply drops of epoxy during the assembly process. Until the molds get modified, we’ll apply epoxy to the current cases that we ship to the EU (CE being EU-specific).

Now that we’ve passed both FCC and CE, we’ll launch PCBA very shortly. Our PCBA contractor is eager to start. Surface-mount assembly is scheduled for next Monday, through-hole assembly is scheduled for later in the same week.

Colored cases

We recently visited a company to choose the colors of the non-black cases. Instead of using their stock colors, we ended up asking for custom colors according to the rendered images that you can see on the order page.

I’m happy to report that the first colored UHK cases just rolled off the assembly line.

We can’t wait to see the colored UHKs fully assembled!

Miscellaneous progress bits

The correct back stickers have finally arrived, and we applied them to the back of the cases. Next, the top and bottom cases are (separately) assembled featuring all the bells and whistles.

We recently noticed that the pad printing of the right case buttons is off. The position of the print has been misaligned by 2 mm. New case buttons will be printed this week.

We also noticed that the LED display was hard to see in bright light, so we asked our supplier for some new samples, and they were able to improve upon the design. Now the manufacturing of 3,000 new LED display films is in progress. They’ll likely arrive next week, at which point, we’ll remove the old films from the displays and apply the new ones.

The outer boxes into which the smaller product boxes will be packed for shipping are being manufactured and are scheduled to be ready next week.

I’ve been super busy with the firmware, landing about 150 commits in the firmware repo since our last update, and released a new version. You’re welcome to read the changelog.

Robi has finished the cross-platform build system of Agent and released versions for Linux, Mac, and Windows. The next step will be the the auto update feature, and integrating the firmware upgrade scripts to Agent, so Agent will be able to update the firmwares of the keyboard halves and modules.

As for the estimated delivery schedule, we plan to send out the 50 pilot run UHKs by the end of November. Then we’ll wait about a week or two for the feedback of the pilot run recipients to make sure that everything is up to snuff. Afterwards, we’ll try our best to launch the delivery of the remaining 1950 UHK of batch 1 in December, but due to holiday season we may have to postpone the shipments to January. We’re trying hard to deliver as soon as possible, but we won’t rush things at the expense of quality.

Thank you for reading this update! We’ll talk to you on 2017-12-14.

22 Responses

When you make changes to the case will you have to re-certify?

Yes, but only a very small subset of the tests which will take about a day.

A great update as always! Congrats on the CE pass, I know you've all worked hard for it, and had to deal with some truly unexpected changes to the Keyboard to make it work. This close to the finish-line (at least the first one) I know we're all happy to see the focus stay on quality, stability, and toughness vs rushing and messing up all your hard work with an avoidable mistake. Thank you again for working so hard and keeping the integrity of your project alive! If there's anything the community can do to assist, I suspect you have but to ask. I'm not sure if I'm in the pilot 50 run (probably not) but will there be a feedback forum or form that we will have access to? I know Google Documents and a few others offer similarly free and easily generated quality feedback forms, in case that helps.

I do have a question regarding the cases and swapping them out, but I'll ask that over on Facebook so you're not having to answer two things at once, I just wanted to pass along my thanks, and in case it gets too busy next month, we wish you and your team, families and friends all a happy holidays, merry Christmas, and a wonderful New Year!

First up, thanks for your encouraging words, and support! Yes, we'll send out a feedback form to all of our backers eventually. I'm sorry to say that you're not in the pilot run. We also wish you a Merry Christmas, and a Happy New Year, although we'll publish another update in the meantime. :)

Them colors!! :)

Will the module (key cluster, etc) cases come in black only or will we be able to specify colors?

Black only, unfortunately. We'd like to provide colored modules but color matching and extra inventory would likely be a huge pain.

Understood.

Congrats on passing CE!

Congratulations on completing the tests. I'll raise a glass to recognize that achievement. Looking forward to completion of assembly and delivery. Hope now that the bureaurats are satisfied with the UHK the remainder of assembly and delivery will proceed smoothly.

Congratulations for also passing the CE-test. I can't wait to get the UHK in my hands. I will be very careful with it because you've added so many effort into the keyboard and project to get it done. Hopefully assembly will go smoothly.

As I am in the pilot run, I get a black keyboard. Can I later order another casing with a different color?

Thanks for the nice words, EdbO! Sure thing, you'll be able to order extra colored cases any time.

Awesome news, congrats!!!

I appreciate the extremely detailed updates. The delay is not a problem - sounds like we're almost there. I think the final product will be worth the wait!

Hey guys - thanks for not compromising on quality!

I have a question (didn't see it mentioned in FAQs or in the comments to previous blog posts). What's the keypress-to-USB latency of UHK? This question was inspired by Dan Luu's blog post about today's keyboards being significant contributors to keypress-to-screen-update latencies: https://danluu.com/keyboard-latency/

Thanks!

Hey Dan, We have yet to conduct such measurements. I expect us to rank quite favorably because our processors are fast and our firmware is fully interrupt based. I'd like to write a blog post about this eventually.

Hey László, Any plans on doing those measurements any time soon? I was reading Dan Luu's article too and would really like to know how my future UHK would compare to other keyboards.

Hey there! I'd like to do such measurements eventually, and optimize the firmware accordingly, but only after things settle down. Right now, we still have to bring the modules to market which take priority.

This has been a very interesting process. Who knew that so much was involved in producing a keyboard? Can't wait to get one and anticipate ordering a second. Thank you for all the hard work on this project!

Comment and question for you.

First amazingly cool project, it took a lot of creativity, hard work, and guts to get this far, so I’m sure you’ll cross the finish line in good form, best of luck to the team involved.

Now to a dumb question. I assume developers are part of the target market? If so, am I the only one that freaked after realizing there is no row for FKeys? I assume there’s a reason it makes sense, but I’ve only recently discovered the whole keyboard subculture, and Ive ead your faq but couldn’t find anything on the subject.

My only baseless guess, is maybe an obsession with compactness and portability (which does look cool) was rationalized by having the ability to remap all fkeys commands to custom combinations?

If that’s the case, I wonder if I’m in the minority by preferring to deal with the bulk. I travel all the time consulting so keeping minimal mass is important. At the same time I don’t want to compromise, occasionally I’ve even carried large monitors along with me if there is nothing decent on site.

The reason its hard to consider remapping not a compromise is because there are always periods where you have to temporarily use someone else’s keyboard. So if I can be efficient with a standard key combination, I’ll try not to remap it to retain muscle memory benefits when driving someone else’s rig, let alone it’s one less thing I have to train myself on.

Thanks and again best to you.

Hi Lee,

Thanks a lot for the nice words!

Yes, developers are our primary target market, indeed. The UHK is a 60% keyboard which basically means that it only features the alphanumeric block of regular keyboards. This design results in minimal hand movement at the expense of heavier chording. It's not for everyone, but many people love it. Luckily, I don't have to use other keyboards, so I'm not sure how hard it is to switch from time to time, and unfortunately, I don't know about such statistics.

Eventually, we'll probably release a 80% keyboard featuring F keys, Esc, and the navigation block, but there's no ETA on that one yet.

Hope I could answer your question. Feel free to follow up with additional questions.

It's pretty normal for keyboards to access the function row by holding a function key and pressing the corresponding button on the number row. For example, the pok3r layout which I am typing on. http://i.imgur.com/7ixnajm.png?1

There are few to no applications that require regular use of the function buttons. The design of traditional keyboards themselves cause this: you have to take a hand off of the keys, probably look down, and move it to a different place in order to hit that one function button, then return to position.

If anything, I find that having this layout strengthens my muscle memory, because it allows you to double-dip with the muscle memory you already have for the number row, which you use way more often without looking down. The function keys become more accessible while requiring zero additional space.

Trevor, thanks for your comments. I respect your preferences, and moreover, try to stay open to the possibility that my own preferences are really inefficiencies, that could be improved.

None of that withstanding, I must say this is objectively not true “There are few to no applications that require regular use of the function buttons”.

I don’t doubt it’s true for the scenarios you work in, but I seen it all the time.

Do you do software development? I’ve noticed one wildcard seems to be how large and how long a person works on a project for on average. I’ve been on the one-project-approaching-os-complexity side for years at a time, but have recently been doing consulting where the projects (or at least how long you work on them) can be much shorter and much more varied. Depth vs. Breadth if you will. That can lead to a preference for what I mentioned, of remapping keys when the efficiency gain is decisive, in order to try and retain speed for multiple environments at once.