Hello and welcome to this month’s UHK update!

TL;DR: Our most recent prototypes have successfully passed EMC pre-compliance testing. The final certification will be taking place in June and is expected to take 4-5 weeks which will push delivery to July. Manufacturing is proceeding apace. One of our prototypes has became a movie star.

You can always check out the expected delivery date and update your shipping address on your Crowd Supply account page.

EMC pre-testing

Not long after our previous update, we assembled 6 prototypes for the upcoming EMC pre-compliance measurement. These are v7.2 prototypes featuring EMC redesigns and related extra components, such as a ferrite choke.

This time, instead of going to T-Network, we went to TÜV which was a much better experience. Their control room is more modern and tidier.

They use a more sophisticated measurement software.

Their measurement chamber is more spacious.

We told you the last time that the laptop we brought didn’t pass the test in itself, so we’ve made sure to bring a MacBook Pro this time to avoid such problems.

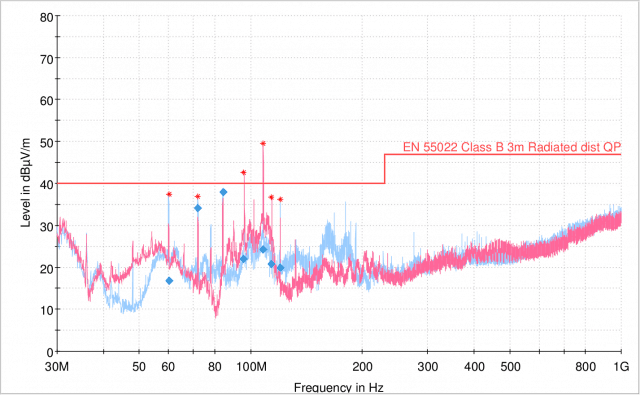

The measurements taken by TÜV are of considerably higher resolution than those at T-Network, and they do take proportionally more time. Instead of taking around 3 minutes, they take about 15 minutes each. This time, we passed the test! You can see the result below.

This may look like a fail, but it's not! There are two peaks that are above the safety zone, but as it turns out, there are two measurements involved. In the first measurement, the peaks get detected. In the second, the peaks are more closely investigated which usually results in considerably lower values. The final values are marked with blue rectangles below the peaks, and they're all within the safety zone.

This is clearly a much better result than anything we’ve ever measured, although admittedly, the safety margin is quite tight around 84 Mhz. Endre has an idea how to make it even better by replacing some components, and we’ll test his idea in a week, but we’ve already booked a certification date for June regardless.

We’ll send two final prototypes to TÜV Hungary by the end of May, who will in turn forward the prototypes to TÜV Netherlands where the actual certification will take place. The certification itself is expected to take 4-5 weeks. This is longer than anticipated and the PCBs can only be mass produced after the certification succeeds. Unfortunately, this pushes delivery to July.

Manufacturing news

Let’s see some major news from the manufacturing department:

- 1,000 steel plates have been manufactured and 3,000 more are in the works. Placement of the switches into the plates will begin soon.

- A pilot run of 100 pairs of the wooden palm rest parts have been ordered, and 900 pairs are set to follow.

- The testing of the modified injection molding tools will take place in a week.

One of our prototypes has became a movie star

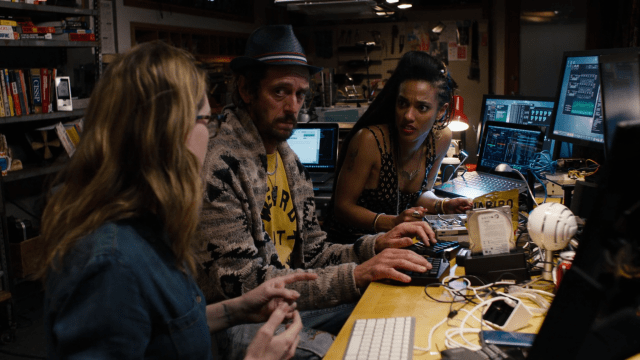

About a year ago, the assistant propmaster of Netflix series Sense8 got in touch with us. She told us that there’ll be a hacking scene in the series, and asked us whether we could provide a prototype to be filmed. Of course, we said yes in a heartbeat. Fast forward one year, we got featured in the series!

You can see the UHK prototype in:

- S2E03 (Obligate Mutualisms): 20:02 (-31:13)

- S2E04 (Polyphony): 2:11 (-55:56) multiple cuts in 10 seconds, 5:01 (-53:06)

And a couple more spots here and there. You’re welcome to let us know if you notice another scene.

Needless to say, we’re thrilled to be featured. Thank you so much for the opportunity, Netflix!

This wraps up our May update, Ladies and Gentlemen. A lot of things are happening in parallel as usual, and with the certification of the PCBs on the horizon, we’re really getting close.

As always, we’ll be keeping you updated on a weekly basis on social media, and on a monthly basis in this blog and our newsletter.

Talk to you on 2017-06-15!

17 Responses

Will the add on modules have to be EMC tested as well?

Yes, very much so.

Did you already assemble one or two keyboards to check if everything fits? Shipping at the end of July is just on time! In the Netherlands we have vacation in August, so I can play my whole vacation with the keyboard .... :-P

Can't wait to have vacation and the UHK :-D

Hi EdbO! Yes, we did assemble a couple prototypes and everything seems to fit well. A vacation with a UHK sounds like fun! ;)

I really hope you will deliver the keyboard and modules before the thermal death of the universe. Before the first EMC test production was 'on schedule' for the end of February, and we can still read 'news' about molds, palm rests and steel parts at the end of May :(

We're sorry for the delay, Domas. Admittedly, (almost) everything takes longer than anticipated. The best we can do is to push forward as hard as we can and keep you updated. We're trying our best to deliver as soon as possible.

I know you guys are cranking away on getting this done. I am very excited to have one of the UHKs and have only recently joined in on the crowd supply (recent being three months ago). With that in mind I think it unlikely that you guys are shipping by the end of July ( from the track record and the fact that you can't manufacture the pcbs until certs are done which are the 4 -5 weeks). So, just moving the date back a month when the delay is likely to take a bit more than a month doesn't seem realistic. I work in product development and if you keep pushing the date back over and over they believe you less and less. If you decide, "You know what we need three months more" and then deliver before you are a hero. I would suggest putting a realistic date up on crowd supply. I know you have had a lot of people waiting for awhile but right now it looks likely that you will disappoint again. I can totally understand putting up a best picture timeline since I am an engineer and just want to see what I make create happiness in my users as soon as possible but that is often going to bite you in the end. Because, as you just commented, everything takes longer than anticipated.

I want to make it clear that I value the work you all are doing and am more excited than ever to see a UHK on my desk. I really appreciate all the updates and know I am likely to receive a response from you almost immediately because you and your team are amazing and doing amazing work. With that kind of dedication and enthusiasm I have no doubt the UHK will be an amazing keyboard.

Thanks so much for taking on this mad passion! I can't wait to see one but I will as long as it takes you guys!

Hi Justin,

There's a lot of truth in what you said. If a further delay will occur, we'll consider moving the delivery date by more than a month for our schedule to be more realistic.

Also, thank you for sharing your enthusiasm for the project. We're so grateful and proud that guys like you are on board!

Let's make this happen together!

I can't criticize you for communicating openly and regularly, but it does worry me how you don't blog about assembly lines and contractor, packaging, shipping, logistics, maybe demonstrating the agent and a fully assembled final product, when you were supposed to ship one month from now.

You don't have to talk about everything, it's just that the "Manufacturing news" which seems to be the most relevant thing to talk about when a product is about to ship, looks very weak in contrast to the strength and depth of the other blog posts covering the prototyping process.

Hi G.Y.,

You're right that the manufacturing news section should have been longer. Now that I think about it, I could have written more about it. It's just so that I've been overly preoccupied with EMC issues lately, and that's probably why I put too much emphasis on them. Also, unlike Andras, I'm not a mechanical engineer, so I'm less focused on those issues than he is. I'll make sure to write more about manufacturing in our next update. I think there'll be plenty of news in that department.

Hi,

Thank you for all of your replies on the blog comments over the months, it means a lot.

Good luck with the final steps.

Hi, my monthly wait is again finally over and it was nice to read an update again :) I'll comment on the delivery date too, since it's a hot topic. I've followed lots of crowd funded projects and all of them have been/are behind the original schedule. Its pretty much the norm. Crowd funding is always a risk both ways and developing a product (especially hardware) is really challenging. Hell, some projects never actually deliver. It's great that you keep us updated very well and the updates are very transparent. This brings confidence. I don't really mind the delays. Some projects fail inform backers at all. This is the best crowd funded project I've seen. Delays are expected, the key is to communicate about it. Thanks for doing that!

I've been super interested regarding the leds, and have some questions. I know they aren't part of the shipped product, but can I just solder them in and they'll work? Did I read somewhere that they're individually addressable? Will built in software support be integrated at some point, and will there be a way to program them by the user? One more: can the brightness of all/ or individual leds be changed? Night mode would rock until I get used to the layout :). I'm also thinking of getting custom caps with translucent labels.

Thanks for the beautiful project!

Hi Richard,

Thanks for rooting for us! Based on your description, you clearly understand the nature and perils of crowdfunding. We've followed a number of crowdfunding campaigns, and according to our understanding, the projects that do deliver on time are fairly trivial in nature, have an exceptionally experienced team behind them, or commercializing an already existing mature open source project. We've seen examples of all of these cases. Other than that, chances are good that the project will be well behind schedule. Thank you for understanding our situation!

Let me write a dedicated blog post on backlighting on the next week. So many people have asked us about it that I feel like I keep repeating myself over and over again. I'll go very deep in this post and link it there.

Thank you for your support, and have a great weekend!

Here's the post on UHK backlighting, just as promised. Cheers!

Would you provide some specs on the bridge cable? How many wires? Gauge? (IIRC, you settled on 24awg, but would like to confirm.) Connector type? Any other important details or gotchas?

I'm going to want to source a custom bridge cable as I like to hold my arms at right angles to my body. (I.e., placing each keyboard half at about the distance of each shoulder). I'm guessing the coiled cable that comes with it isn't going to be able to stretch that far. :) Thanks!

Hi Micah,

Here are the specs:

By design, it's pretty standard stuff. Most (if not all) telephone cables should work. You're welcome to ask me if you have other questions. :)

Thank you for your support!

dr. House have one.. now I totally want one too!!1